FIND TMI TATSUMI PARTS FOR YOUR VEHICLE

FIND TMI TATSUMI PARTS FOR YOUR VEHICLE The braking system of a vehicle is the cornerstone of its operating safety. As a result, the safe operation of all parts and assemblies of the braking system is a prerequisite for allowing a vehicle to be driven on public roads.

The primary goal of a car's braking system is to reduce speed, stop the vehicle (even in an emergency), and keep it in place for a long period (parking). It turns out that notions like the working (main) and parking brake systems must be distinguished.

Furthermore, contemporary automobiles are fitted with a variety of auxiliary systems that rely on braking system components to function. Anti-lock, recoil, and traction control systems, as well as a directional stability system, are examples of auxiliary solutions. Their introduction can significantly improve the safety of driving.

The functioning elements of the vehicle's braking system - brake pads, brake drums, and discs - are the most sensitive to wear. As a result, when performing vehicle maintenance, these parts must be updated often (brake pads are considered consumables and are changed most often).

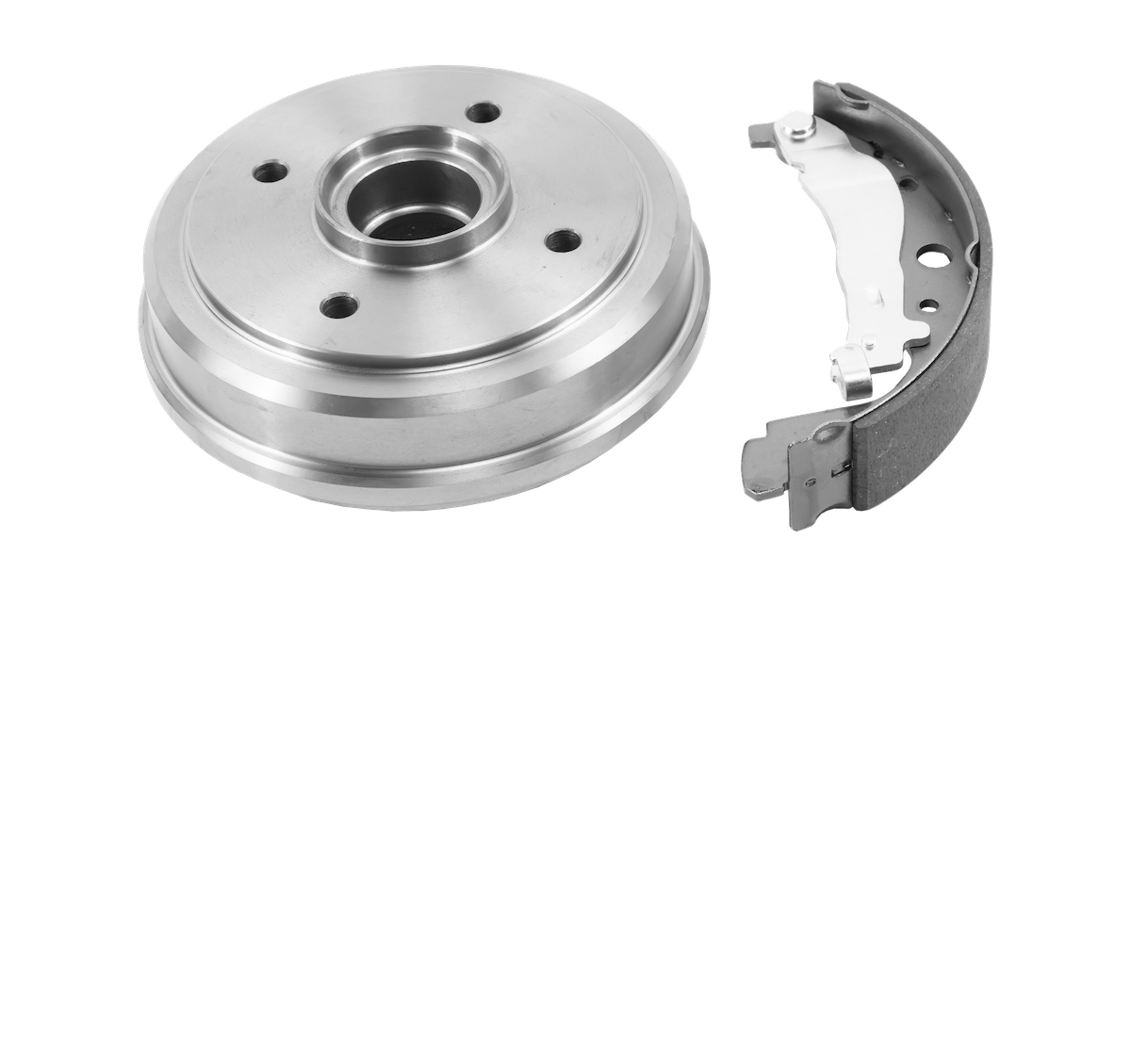

Drum brakes are regarded ethically outdated, and disc brakes have entirely replaced them in many current automobiles, yet they still offer a number of undeniable advantages, making it premature to dismiss them. They are inexpensive, simple to make, and their technology has been refined over decades of use. Disc brakes are more efficient, work better in hot weather, are easier to maintain, and are smaller and lighter than drum brakes.

The frictional force that transforms kinetic energy into heat is used by brake pads with specific friction linings that are pushed against the brake discs or drums for braking (and/or halting) the automobile. The brake pads are subjected to extreme wear as the operation proceeds, their friction linings progressively wear out, and the pads must be changed with new ones (in case of complete wear or destruction of the friction linings, the braking efficiency decreases sharply, there is a grinding noise during braking, and the working surfaces of the disc or drum very quickly come out of building).

TMI TATSUMI brake pads meet or exceed all of the most stringent road safety rules, including ECE R90. TMI TATSUMI brake pads employ high friction material to provide uniform and effective vehicle braking while also extending the life of discs and drums by allowing them to wear more evenly.

TMI TATSUMI brake pads are made up of at least twenty separate components and come in five different friction material choices. The formula for the composition is chosen based on the car's characteristics: for example, most Japanese and Korean automobiles employ the formula "NON-ASBESTOS ORGANIC," which is characterized by a low level of dust generation and a total lack of squeak. Organic (carbon-containing) components are used in the friction linings to produce this effect.

A friction mixture "SEMI-METALLIC" with a content of steel shavings in the composition is used as part of the friction linings of the TMI TATSUMI brand brake pads on heavy vehicles, primarily for commercial purposes (vans, trucks, etc.), to ensure reliable frictional properties under increased loads on the brake system and to further increase the service life.

Only TMI TATSUMI brake pads with the "LOW-METALLIC" formula are approved for a variety of European vehicles. These pads are recognized by the presence of a minor amount of steel shavings in the friction substance, which is mostly replaced by unique synthetic fibers. LOW-METALLIC brake pads provide optimal braking performance in all humidity and temperature situations, making them suitable for use in high-performance passenger automobiles.

The use of unique noise-suppressing linings in the manufacturing of all TMI TATSUMI brake pads eliminates noise and vibrations that occur while braking, preventing the development of undesirable noises (squeaks and whistles).

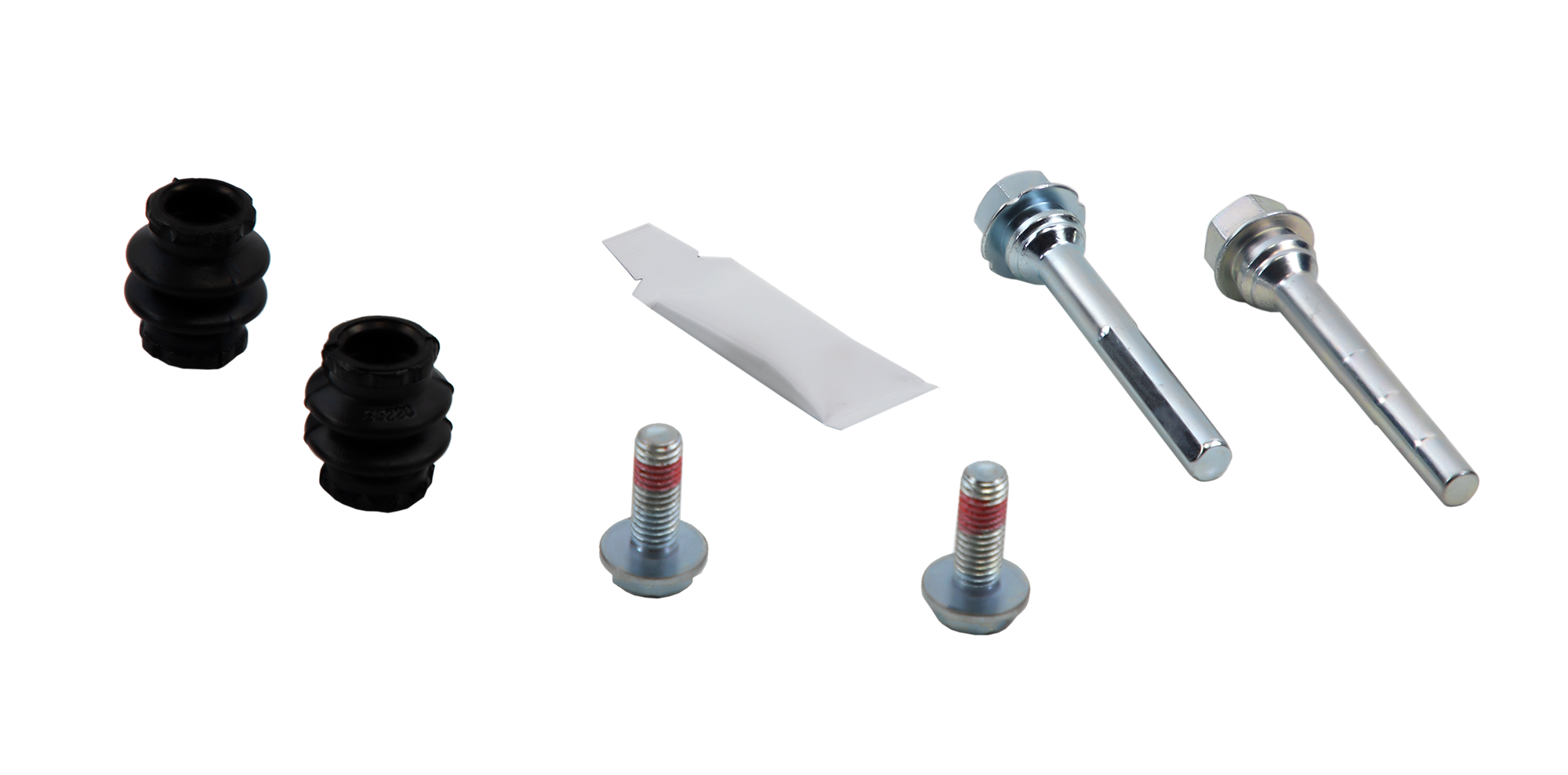

In the event of excessive wear, jamming during operation, or breakdown of brake caliper parts, the entire caliper must be replaced right away, or it must be fixed with a specific repair kit, replacing only individual pieces.

All OEM standards and OE measurements are met by TMI TATSUMI brand repair kits. The use of synthetic rubber in the TMI TATSUMI caliper repair kits ensures the braking mechanism's longevity and dependability in a variety of temperatures and under the impact of various hostile media. The exceptional corrosion resistance of all metal parts included in our repair kit will not go unmentioned.

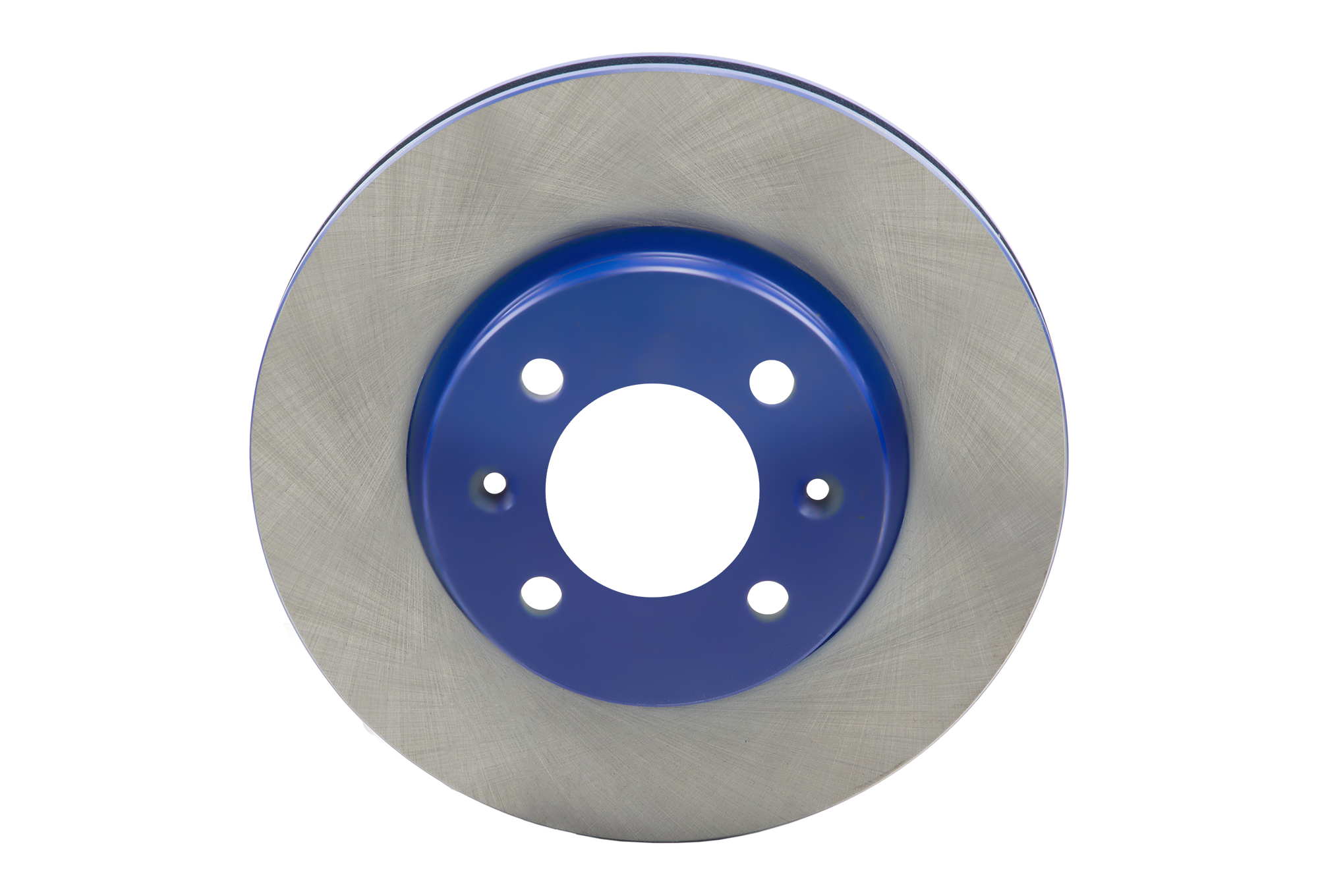

During operation, under the action of frictional forces from the side of the brake pads, brake discs and drums gradually wear out, and their working surfaces wear out. In addition, corrosion (due to exposure of discs and drums to water and humid air) accelerates their wear. For further safe operation of the vehicle, when significant wear of these parts is reached, they must be replaced with new ones.

All OEM standards and OE measurements are met by TMI TATSUMI brand repair kits. The use of synthetic rubber in the TMI TATSUMI caliper repair kits ensures the braking mechanism's longevity and dependability in a variety of temperatures and under the impact of various hostile media. The exceptional corrosion resistance of all metal parts included in our repair kit will not go unmentioned.

High-quality raw materials used in the production of TMI TATSUMI brake discs and drums make it possible to guarantee their reliability, durability, stability and predictability in operation. Brake discs and drums from our range fully correspond to the characteristics of original parts and retain their original properties throughout the entire service life, even with the most active use of the vehicle.

-

OE qualityOE quality

Our products are manufactured in state-of-the-art factories that supply conveyor belts to leading car manufacturers.

- - Careful selection of materials and components

- - Quality control at all stages of production

- - Product testing in our laboratories

-

Wide range ofWide range of

More than 15,000 articles of premium car components applicable to a wide variety of car modifications.

-

Product availabilityProduct availability

- - Stable availability and regular replenishment of goods in all warehouses

- - An extensive distribution network

- - 100% availability in our distribution warehouses

- - Instant and error-free order processing

-

Warranty 24 monthsWarranty 24 months

By purchasing our products, the buyer can return them within two years after the identification of a manufacturing defect. Learn more about the warranty.

-

360 customer support˚360 customer support˚

For us, the client always comes first, so we offer you:

- - Customer service 24/7

- - Hotline for technical support

- - Up-to-date catalogs and post-sales support

-

Fair pricesFair prices

Premium quality at an unbeatable price.

We are constantly improving production and optimizing logistics processes in order to offer our customers the best price.