FIND TMI TATSUMI PARTS FOR YOUR VEHICLE

FIND TMI TATSUMI PARTS FOR YOUR VEHICLE The air entering the engine used to be cleaned by passing it through a cloth saturated in oil. Partially filtered oil filters screened pollutants from just a portion of the flow, and the fuel was frequently settled rather than filtered. Filtration now uses the most advanced synthetic materials with absolutely amazing characteristics, thanks to technological advancements.

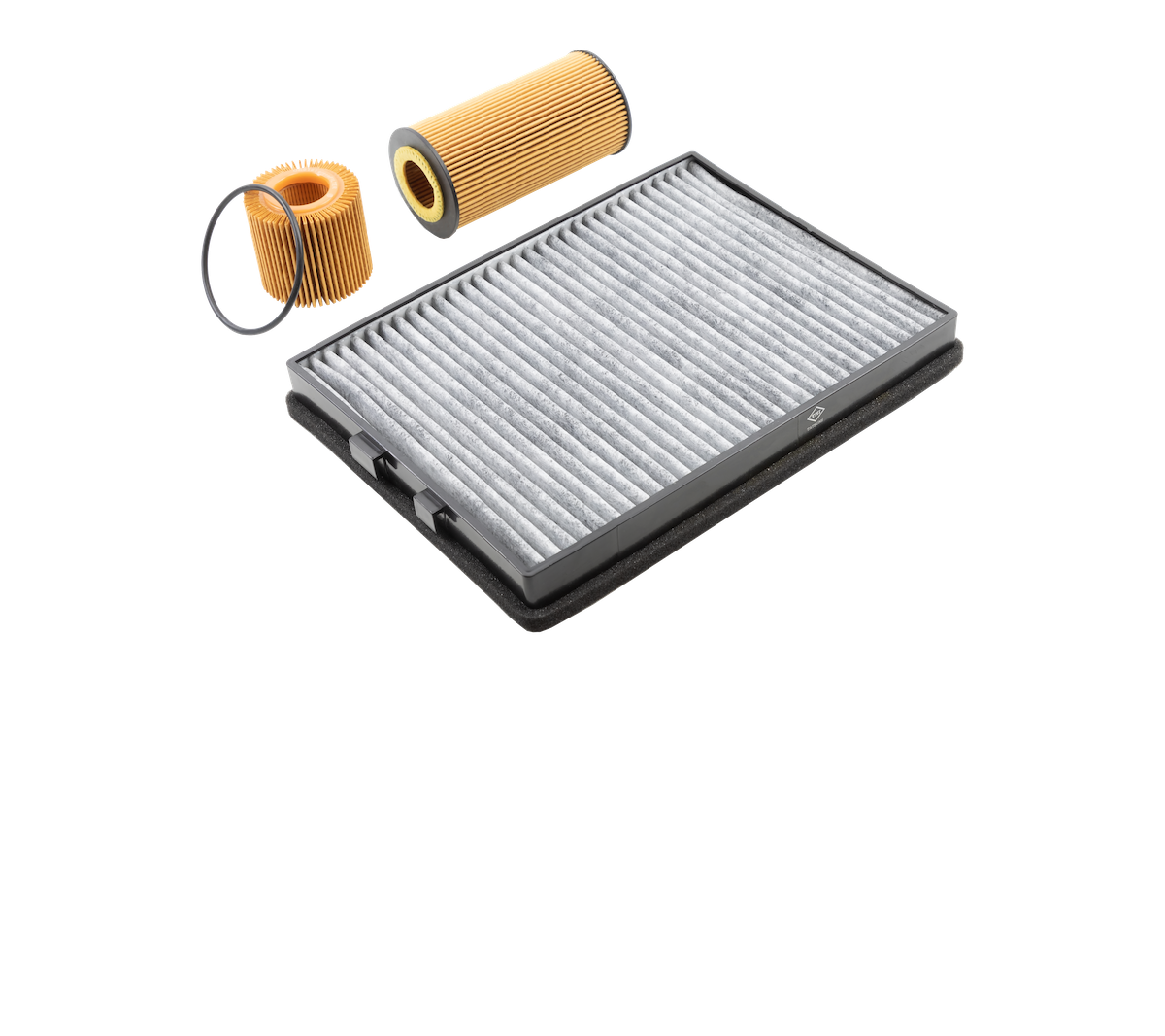

There are four basic types of filters used in modern cars:

- Air. Their job is to remove any foreign solid particles and inclusions from the air entering the engine.

- Fuel. This sort of filter's job is to purify car gasoline thoroughly to remove any suspended particles, dirt, and debris. Water can also be removed from the fuel using the sediment filter.

- Oil (for internal combustion engines and automatic transmissions). The primary goal of utilizing these filters is to remove carbon particles, wear products from mechanisms, and other contaminants from the oil.

- Air cabin.These filters are used to filter the air that enters the vehicle.

Filters substantially improve the car's smooth functioning and comfort of operation (especially in metropolitan areas, if we talk about cabin filters). Untimely replacement of old filter components with new ones obviously has a bad impact on the car's technical state and can result in a reduction in the resource of systems and assemblies, as well as their early failure.

A good replacement filter element should have an optimum balance of features such as excellent filtering, low flow resistance, and high absorption capacity while not lowering throughput much. There's no use in talking about the filter's overall operational efficiency if each of these characteristics isn't performing well.

Significant quantities of well-purified air are necessary for a lengthy and steady functioning of the car's propulsion system. Abrasive dust particles may quickly damage surfaces like cylinder mirrors, valve stems, working edges of piston rings, and other surfaces if air purification is insufficient.

A replacement filter element of the automobile air filter cleans the air entering the engine. In addition to the high requirements for the quality of this cleaning, it is also critical to minimize the resistance from the filter side to the flow of incoming air; otherwise, there will simply not be enough air for normal operation of the power plant, resulting in increased wear of parts, reduced power, and increased fuel consumption.

Furthermore, manufacturers all over the world are battling to enhance filter capacity, which is critical in tough vehicle operating circumstances with high dust levels (on dirt roads, in dry hot climates, etc.). The longer the filter element holds dust without sacrificing sufficient throughput for regular engine performance or lowering air purification quality, the more durable and efficient the car's operation will be.

TMI TATSUMI air filters feature the ideal combination of low airflow resistance, big capacity, and high filtering quality (about 99 percent ). The extensive use of sophisticated contemporary composite materials in the manufacturing of our filter components has a big influence on their distinctive characteristics.

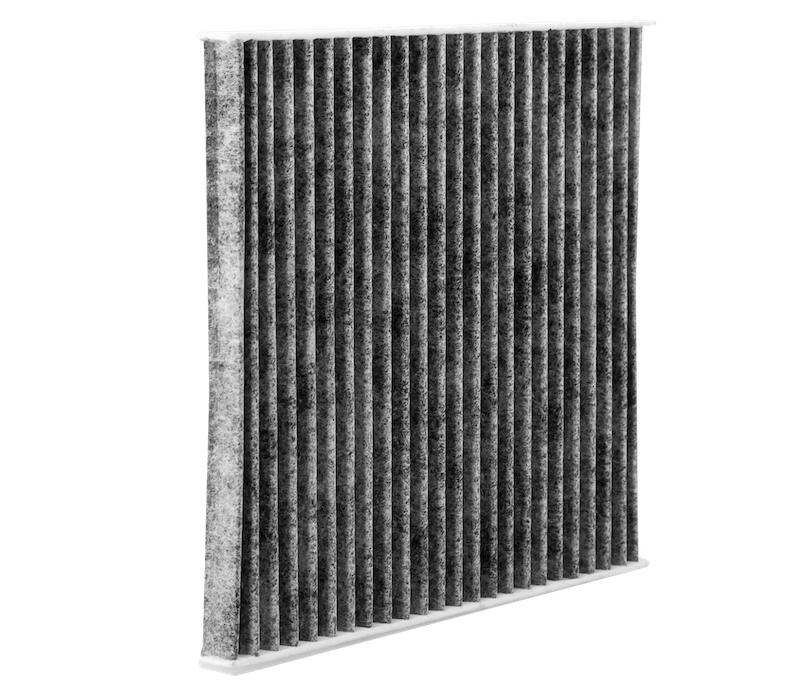

Cabin filters, which are kinds of air filters, are used to guarantee the purity of the air in the automobile cabin. In addition to the well-known anti-dust cabin filters, the TMI TATSUMI brand now offers a growing number of options with a carbon layer in their design, which can reduce the concentration of various harmful substances in the cleaned air, as well as filter elements with the addition of various types of disinfecting, antibacterial connectios. The TMI TATSUMI cabin filters are made of a new composite material that is extremely efficient.

High-quality filtering of engine oil from any suspended particles (for example, metal particles and carbon deposits, soot) is required to ensure the long and dependable functioning of an automobile engine.

TMI TATSUMI oil filters and cartridges are made of a sophisticated composite material that provides excellent filtering (up to 99 percent ). The filter element's high strength allows it to efficiently filter even extremely heavy oil (for example, after a long stay at negative temperatures). Our filters' contamination capacity allows them to securely filter the oil at the maximum level for the whole time between filter and oil changes.

Our oil filters have built-in bypass and anti-drain valves made of EPDM (ethylene propylene rubber) or silicone that ensure trouble-free operation of the filter even in the event of a sudden pressure surge in the oil supply system and prevent even short-term operation of the power plant in conditions of insufficient lubrication of its moving parts.

Chemical resistance is a feature shared by all components of TMI TATSUMI oil filters, which contributes to their long-term dependability.

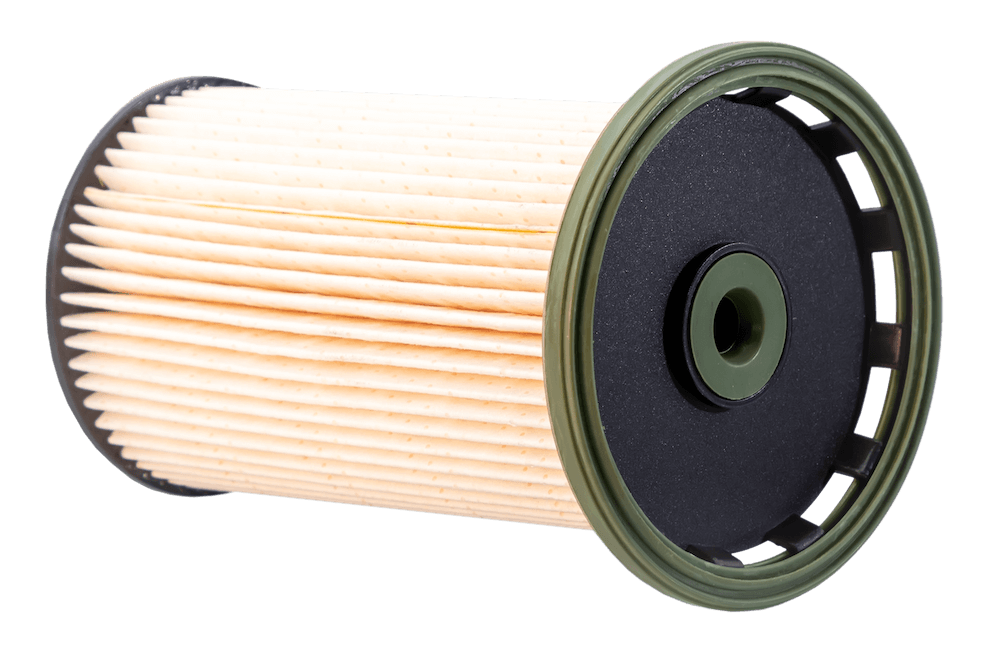

A thorough cleaning of the gasoline flowing from the tank is required for a contemporary injection or diesel car power plant; otherwise, a number of components can soon become useless. Injectors, high-pressure fuel pumps (high-pressure fuel pumps), and the catalytic converter of exhaust gases are all affected by fuel contaminants. Special gasoline filters are used to remove inclusions from the fuel. In current passenger automobiles, they are frequently fitted as a single unit with a gasoline pump directly in the fuel tank.

TMI TATSUMI gasoline filters and cartridges are made from contemporary composite materials that have the best filtering efficiency and minimal resistance in the filter element. TMI TATSUMI fuel filters are distinguished by their great chemical resistance, the fact that they do not need to be replaced frequently, and the fact that they operate reliably even under extreme temperatures.

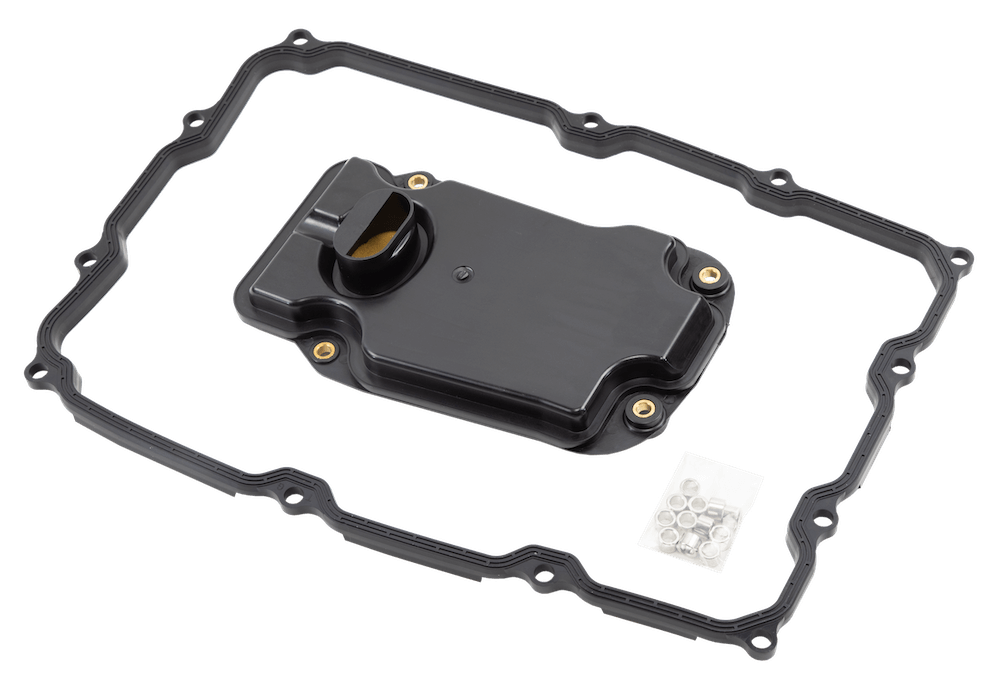

ATF is a transmission fluid (oil) used in automatic transmissions. It transfers torque from the engine to the gearbox, as well as lubricating all moving components and assisting in the shifting mechanism's performance. The transmission fluid becomes polluted with different wear products of moving components over the course of completing all of these duties, necessitating regular and high-quality filtering.

The TMI TATSUMI brand offers a choice of automatic transmission filters made of a contemporary composite material that has been enhanced. Our filters feature a one-of-a-kind mix of high flow rates (low fluid flow resistance) and efficient filtering of even the tiniest particles. The filter's capacity is sufficient for long-term operation without substantial deterioration due to the deliberate positioning of the filter material inside the filter. In addition, gaskets are included with a variety of TMI TATSUMI branded automatic transmission filters when they are replaced.

All components of our filters have a consistently high chemical resistance throughout the entire period of their operation.

-

OE qualityOE quality

Our products are manufactured in state-of-the-art factories that supply conveyor belts to leading car manufacturers.

- - Careful selection of materials and components

- - Quality control at all stages of production

- - Product testing in our laboratories

-

Wide range ofWide range of

More than 15,000 articles of premium car components applicable to a wide variety of car modifications.

-

Product availabilityProduct availability

- - Stable availability and regular replenishment of goods in all warehouses

- - An extensive distribution network

- - 100% availability in our distribution warehouses

- - Instant and error-free order processing

-

Warranty 24 monthsWarranty 24 months

By purchasing our products, the buyer can return them within two years after the identification of a manufacturing defect. Learn more about the warranty.

-

360 customer support˚360 customer support˚

For us, the client always comes first, so we offer you:

- - Customer service 24/7

- - Hotline for technical support

- - Up-to-date catalogs and post-sales support

-

Fair pricesFair prices

Premium quality at an unbeatable price.

We are constantly improving production and optimizing logistics processes in order to offer our customers the best price.