FIND TMI TATSUMI PARTS FOR YOUR VEHICLE

FIND TMI TATSUMI PARTS FOR YOUR VEHICLE The primary function of the vehicle suspension is to connect the sprung and unsprung masses. The suspension system in an automobile is a complicated system of interconnected parts and systems.

The car suspension guarantees consistent and reliable contact between the vehicle wheels and the road surface, smoothing out any surface irregularities, and effectively and safely transferring torque from the engine and braking power. In addition, the suspension has a direct impact on the vehicle's steering efficiency.

The suspension is made up of three basic parts: elastic, damping, and guiding. The elastic component (springs, springs) guarantees that the vehicle runs smoothly on uneven roads and that vertical vibrations of the sprung mass are reduced. The dampening component (shock absorbers) is responsible for damping body vibrations by turning the kinetic energy of the sprung mass into heat through friction. Under the action of the ensuing stresses and vibrations, the guide component maintains the precise wheel alignment angles and their correct position relative to the car body. Suspension components can be built in a variety of ways structurally, but their purpose remains the same: to smooth and dampen vibrations, as well as to eliminate vibrations and noise that occur when driving over uneven road surfaces.

There are already a vast variety of various automobile suspension systems on the market, each with its own set of technological features. The McPherson suspension is the most prevalent suspension in passenger automobiles.

In most passenger cars, the front suspension is completely independent. Unlike the front, the rear wheel (or rear axle) suspension is usually dependent or semi-independent, as this is sufficient for a more or less comfortable vehicle operation. More sophisticated rear suspension options are more costly and are often offered in passenger automobiles starting in the mid-price range. Advanced rear suspension options are more expensive and are often available in passenger automobiles priced from the mid-range to the high-end.

There are several more possibilities for automobile suspension design, ranging from unusual to quite exotic. For example, pneumatic, hydropneumatic, and even electromagnetic suspension can be distinguished based on the technological principles of execution. There are also active (adaptive) suspensions, which are near-perfect in their properties, with manual and/or automated adjustment of a number of their parameters to road conditions and, in certain implementations, a near-ideal degree of body vibration dampening.

The capacity to modify vehicle characteristics for individual road conditions is the major benefit of adaptive suspensions. On a high-speed motorway, for example, the suspension can be stiffer and the ground clearance reduced (improving the car's handling), but when traveling through difficult terrain, the suspension can be improved to absorb vibrations from road imperfections and elevate the car higher. The disadvantages of such pendants are their complexity, the quantity and weight of pieces, maintenance challenges, and, of course, the cost.

Suspension components, like everything else in the universe, wear down and fail over time. Because the safety of a vehicle's movement is directly dependent on its condition, suspension parts must be replaced on a regular basis. In this instance, the quality of the replacement parts used in the repair and maintenance directly affects not only the vehicle's own safety but also the safety of other road users.

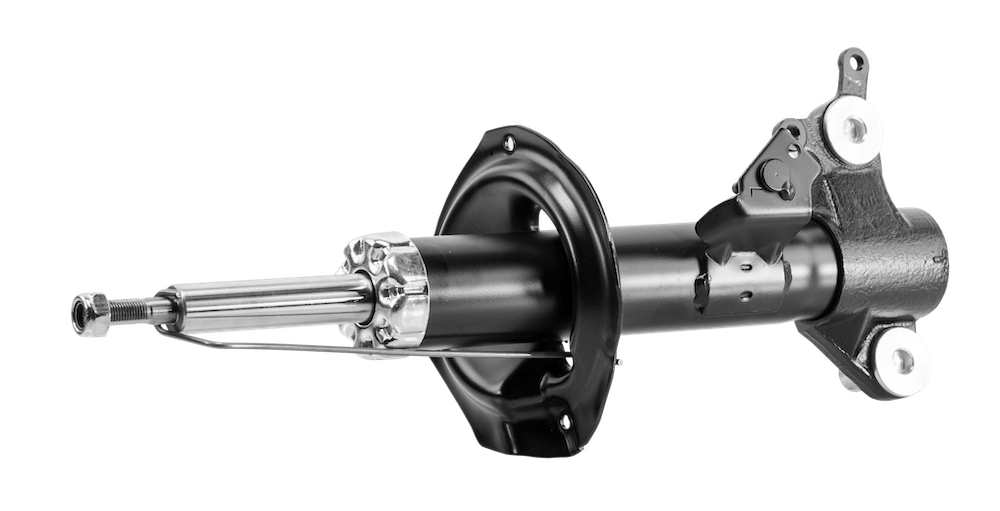

When an automobile travels over uneven terrain, a shock absorber dampens (damps) vibrations and stabilizes the vehicle. Vehicle roll is also reduced by shock absorbers during maneuvers, acceleration, and braking.

It's risky enough to drive a car with defective shock absorbers; it can result in a loss of control on the road. Furthermore, faulty shock absorbers must be changed as quickly as possible to avoid damage to the body and surrounding suspension parts (at the attachment points)

TMI TATSUMI shock absorbers are known for their high-quality performance and use of Nok (Japan) premium lubricants and oil seals for long, efficient, and smooth operation. The rods are polished and thermally treated with a unique anti-corrosion coating, ensuring a long service life for the shock absorbers while maintaining their original features, as well as outstanding performance even in the most extreme vehicle operating circumstances.

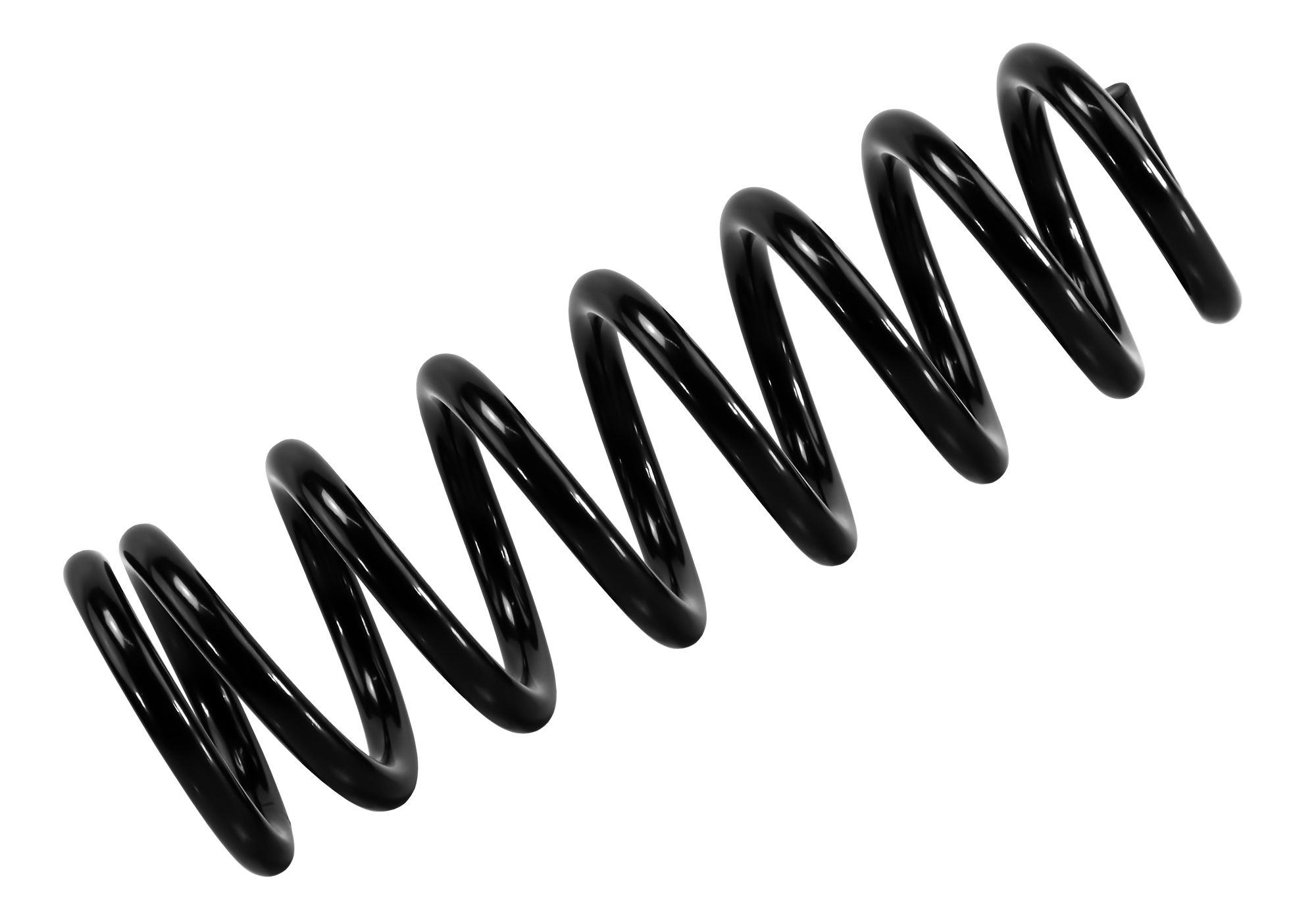

Elastic suspension components (springs in most contemporary automobiles) absorb kinetic energy from the chassis (compressing and stretching) and reduce the impacts and shocks sent to the car body by the wheels. The stiffness and geometric dimensions of the elastic components influence the mass of suspension characteristics, as well as the ground clearance and total carrying capacity of the vehicle.

Damaged, fractured, shrunken, and worn springs must be changed as soon as possible, or else other components of the car's suspension may fail, resulting in body damage.

TMI TATSUMI brand springs are composed of special spring steel and are heat treated (hardened) throughout the manufacturing process to optimize performance and service life. They are also coated with a unique anti-corrosion coating that prevents rust foci from forming.

The shock absorber support is an integral part of every contemporary vehicle's damping system. Its primary responsibility is to secure the shock absorber to the body and to transfer the load to it. For the execution of safe mobility, this component's serviceability is critical. Cracks and chips in the surface are undesirable mechanical flaws.

The optimum mix of elasticity of its damping components and total structural strength distinguishes TMI TATSUMI supports. The chemical composition of the material of polymer elements with the addition of synthetic rubber determines the stable operation of shock absorber supports over a wide temperature range, which is determined not only by design features but also by the special chemical composition of the material of polymer elements with the addition of synthetic rubber.

The shock absorber rod's smooth operation is primarily due to the boot, which prevents different abrasive and chemically active substances from entering the rod. A high-quality boot should be resistant to oil and gas, and its mechanical strength should be sufficient to maintain its shape and perform its functions under constant cyclic load in summer and winter temperatures, UV radiation from the sun, abrasive and chemical effects from road dust, bitumen, oil, gasoline, and other substances.

A well-constructed shock absorber bumper can resist a considerable shock load while maintaining its original characteristics throughout its service life. Typically, low-cost versions of this item are manufactured of unstable materials that soon acquire excessive hardness and brittleness, resulting in cracking and premature destruction (especially in winter conditions).

TMI TATSUMI anthers and bumpers have an ideal mix of flexibility and strength, and the synthetic rubber used in their production provides a long service life at a variety of ambient conditions. The quality of spare parts sold under the TMI TATSUMI brand is comparable to that of genuine components used on automobile assembly lines.

Ball joints' principal function is to pivot the wheel hubs to the vehicle's suspension arms. When driving slowly on an uneven road, particular sounds, bumps, and bangs may signal a breakdown of the suspension ball joints. Loss of front-wheel stability (play) is also a symptom of considerable wear on the ball joints.

Internal friction has been considerably reduced in TMI TATSUMI ball joints thanks to highly polished working surfaces, high-performance grease with a long service life, and a variety of unique technical solutions. In both summer and winter circumstances, the choice of synthetic rubber as a boot material offered dependable protection against any contamination of the unit.

TMI TATSUMI ball joints are made of high-quality steel that has been treated to resist corrosion and can withstand a wide range of stresses. Furthermore, the liner's unique shape does not obstruct the flow of lubrication to the loaded surfaces.

Important components of the vehicle steering system include steering tips. They are primarily concerned with the safety of motorists. When the liner wears down, a backlash occurs in the tip and progressively grows; in a car, a distinctive tapping may be heard, and the steering wheel's free play increases (the steering wheel will become "empty"). As the liner wears out, the amount of free play in the tip rises (the more free play in the tip, the higher the shock load on the liner), as does the risk of an accident.

The TMI TATSUMI brand offers steering tips with a unique ball pin shape that lowers internal joint friction and, as a result, liner wear. The combination of anthers and synthetic rubber provides dependable mud, dust, and snow protection. Significant-quality lubricant incorporated in the tip hinge allows the device to operate even in extreme temperatures and under high mechanical stress.

"The anti-roll bar is connected to the suspension elements by stabilizer rods, which impart strengthening forces to them. In a passenger automobile, the stabilizer's main job is to maintain maximum stability during maneuvers and turns, decrease body roll, and enhance handling. The comfort in the car compartment reduces as the resource of the stabilizer rods grows, as does the level of traffic safety. "

Internal friction may be reduced and component life can be extended by using a specific ball pin profile in the joints of the TMI TATSUMI stabilizer links, thorough polishing, and the use of high-quality lubricants with a high degree of efficiency at all temperatures.

Furthermore, the long life of our brand's stabilizer links is due to the use of high-quality synthetic rubber anthers that are flexible and stable throughout a wide temperature range.

Special supports link the engine and gearbox (internal combustion engine and gearbox) to the vehicle body, reducing vibration loads and noise transmission.These bearings lose their flexibility and capacity to absorb vibrations as they wear out, and as a result, more and more noise and vibration is transferred to the body. The level of interior comfort is decreased. The fasteners are exposed to more and more stresses as the supports wear down, and these components can easily be pulled away from their installation sites.

The use of robust synthetic rubber in the production of TMI TATSUMI engine and gearbox mountings ensures their dependable retention and a high level of stress absorption at the places of connection of these components to the automobile body or to the suspension parts.

The great chemical stability of these components, as well as the preservation of the utilized materials stipulated at the outset, ensures their effective functioning throughout their full service life. Synthetic rubber in these components has performed admirably in a wide range of temperatures.

The forces transferred to the wheels by the steering system through steering rods cause the angles of rotation of the car's wheels to alter while navigating. It is possible to select the right toe angle by setting the pairs "steering rod - steering tip" (and the correct position of the steering wheel when the vehicle is moving in a straight line).

A major accident might be caused by excessive wear, malfunction, or mechanical breakdown of the steering rods.

Internal friction in the pivot joints was reduced thanks to the design elements of the TMI TATSUMI steering rods and the use of high-quality lubricant in them. Furthermore, our steering rods have a long service life due to the careful treatment of all working surfaces and the dependable anti-corrosion coating on their surfaces.

Stabilizer bushings and quiet blocks are rubber-metal components that are used to attach suspension elements to the vehicle body while also minimizing noise and vibration. The state of these goods impacts not only the level of comfort in the cabin, but also the whole suspension system's efficiency. When they wear out, the vehicle's overall safety is compromised.

TMI TATSUMI rubber-metal products are designed to strike the perfect balance between flexibility and mechanical strength. Our experts were able to establish steady operation of these components over a wide temperature range by adding synthetic rubber to the rubber, as well as assure their great endurance.

Depending on the design, TMI TATSUMI levers are made using sophisticated equipment utilizing high-precision casting or stamping. The levers' strength properties are completely constant, and they frequently outperform parts fitted on vehicle conveyors.The application of a special anti-corrosion coating guarantees a long service life even in the most severe climatic conditions. Since they contain ball and silent blocks, their distinctive characteristics are also combined.

-

OE qualityOE quality

Our products are manufactured in state-of-the-art factories that supply conveyor belts to leading car manufacturers.

- - Careful selection of materials and components

- - Quality control at all stages of production

- - Product testing in our laboratories

-

Wide range ofWide range of

More than 15,000 articles of premium car components applicable to a wide variety of car modifications.

-

Product availabilityProduct availability

- - Stable availability and regular replenishment of goods in all warehouses

- - An extensive distribution network

- - 100% availability in our distribution warehouses

- - Instant and error-free order processing

-

Warranty 24 monthsWarranty 24 months

By purchasing our products, the buyer can return them within two years after the identification of a manufacturing defect. Learn more about the warranty.

-

360 customer support˚360 customer support˚

For us, the client always comes first, so we offer you:

- - Customer service 24/7

- - Hotline for technical support

- - Up-to-date catalogs and post-sales support

-

Fair pricesFair prices

Premium quality at an unbeatable price.

We are constantly improving production and optimizing logistics processes in order to offer our customers the best price.