FIND TMI TATSUMI PARTS FOR YOUR VEHICLE

FIND TMI TATSUMI PARTS FOR YOUR VEHICLE TMI TATSUMI brake discs and drums are made using high-quality raw materials that ensure their dependability, longevity, stability, and predictability in operation. Our brake discs and drums closely match the characteristics of original components and keep their original qualities throughout the service life of the vehicle, even under the most strenuous conditions.

Transmissions are classified by the sort of drive they provide. The vehicle's rear wheels, front wheels, or all wheels at once (so-called four-wheel drive) can all function as the vehicle's leading wheels. The architecture of the vehicle transmission can vary substantially depending on the kind of drive.

The engine and gearbox are usually separated by a clutch in the generally recognized design of a contemporary gasoline or diesel vehicle's transmission, with the aim of disconnecting them for a brief period (for example, to change gears) and smoothly reconnecting them. The gearboxes of traditional front-wheel drive and rear-wheel drive automobiles, however, change substantially beyond the checkpoint.

The differential and main gear are generally situated directly in the gearbox of a front-wheel drive passenger automobile, from which the engine torque is transferred to the front drive wheels through axle shafts and constant velocity joints (constant velocity joints). The engine torque is delivered through the gearbox to the main gear and differential (placed in the rear axle) through the propeller shaft, and then via the axle shafts to the driving rear wheels in a conventional rear-wheel drive vehicle.

Electric cars have grown in popularity in recent years. One of its advantages is that the transmission is much simplified. Only a single-stage gear reducer functions as a transmission when linked to each wheel of its own electric motor. When the engines are placed in the wheels, the transmission is essentially electronic.

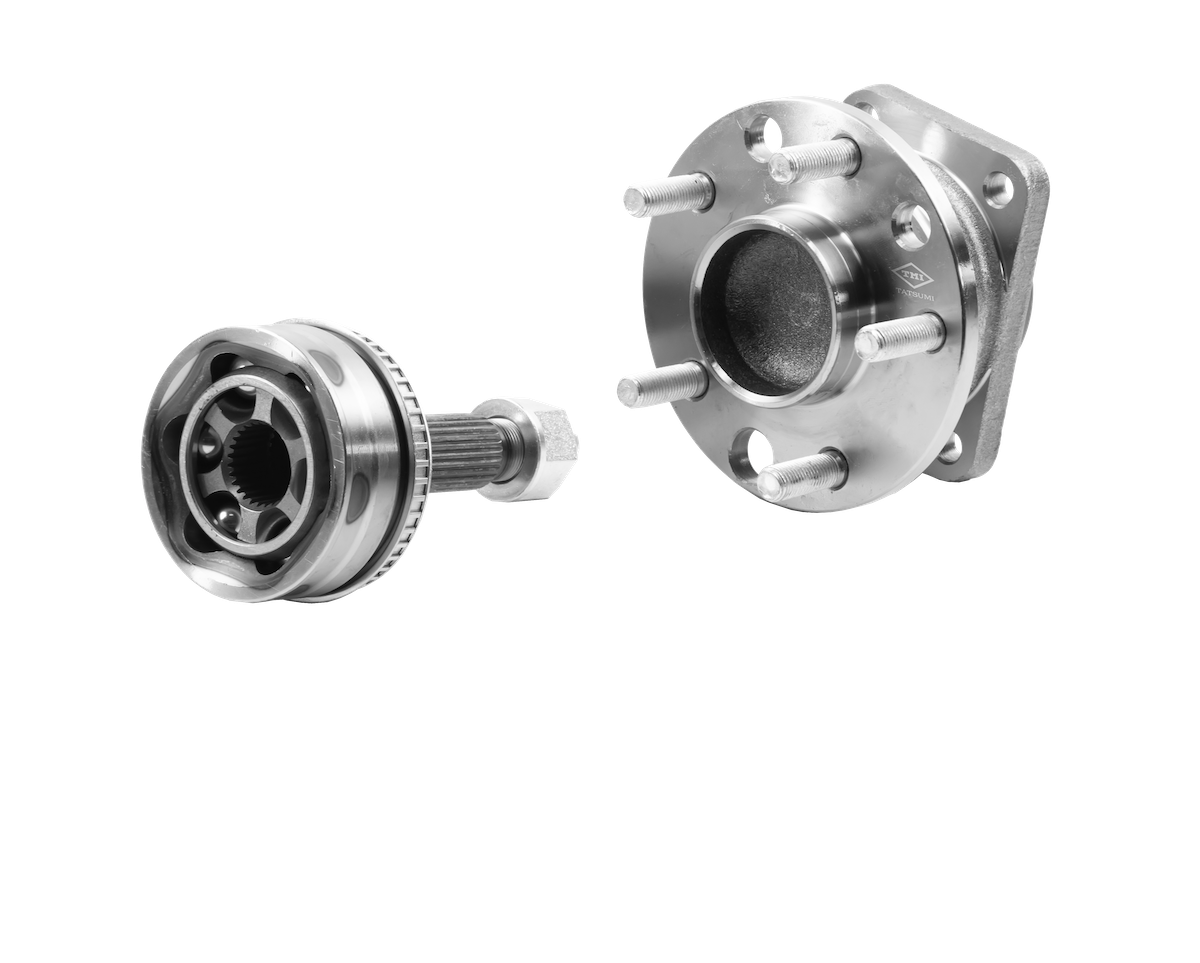

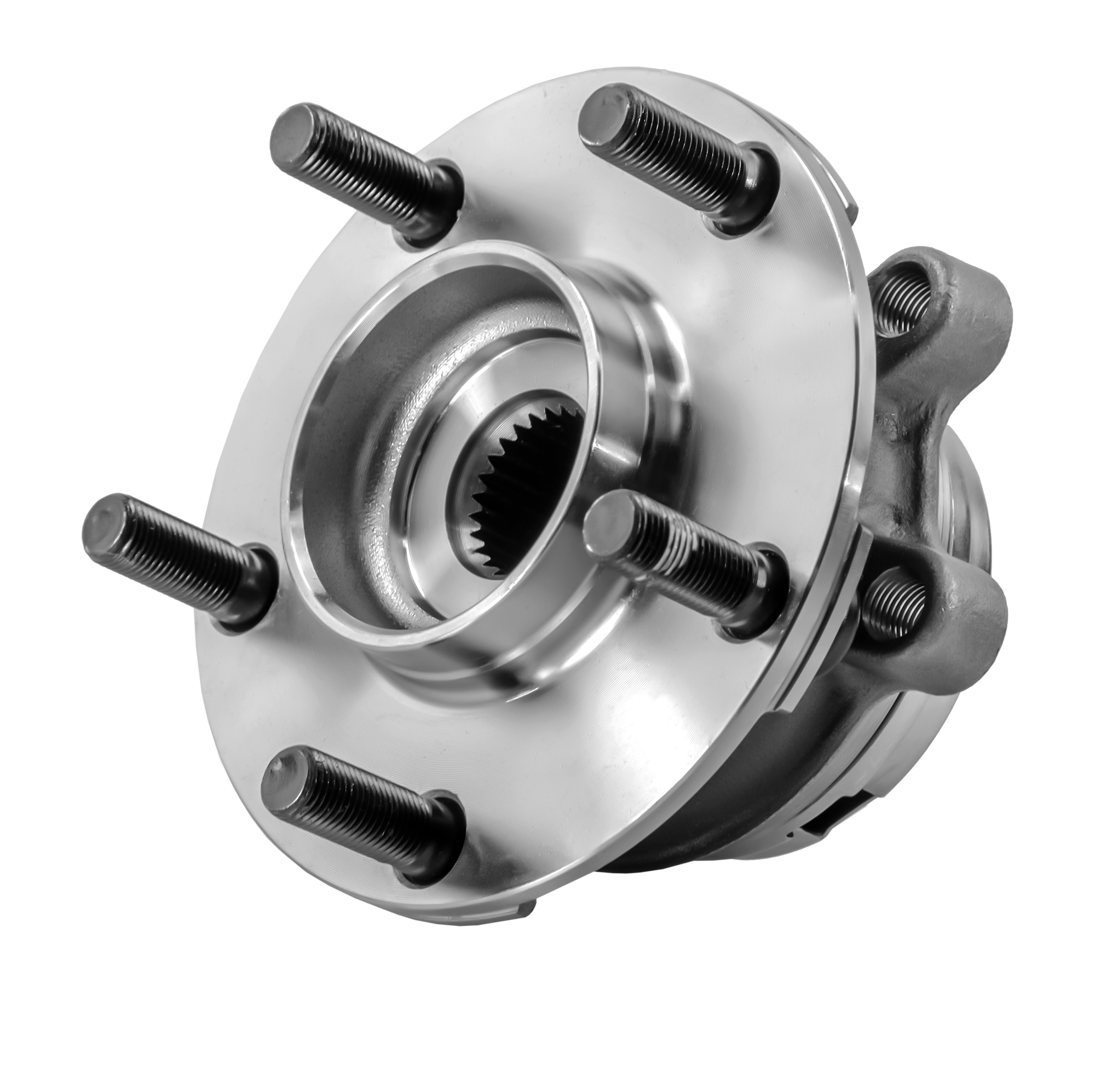

The device that connects the vehicle's suspension to a bearing system that allows the wheels to move freely is known as the wheel hub. The hub units have the greatest direct impact on the vehicle's handling. Their failure might result in an unexpected shift in the vehicle's trajectory and the possibility of an accident.

TMI TATSUMI wheel hubs and hub bearings are composed of high-quality steel and have hardened running surfaces to provide maximum hardness and strength. To optimize friction and yield, ball bearing tracks are meticulously polished. Furthermore, our bearings employ JIS (Japanese Industrial Standards)-compliant balls, which adds to a longer bearing life.

A unique gland seal is used in TMI TATSUMI brand bearing units to provide dependable protection against the impacts of unfavorable external conditions, dirt, and abrasive particles. A high-performance grease is also used to reduce internal friction and related wear and tear, and it is meant to last a long period without needing to be replaced.

For direct torque transfer from the gearbox to the drive wheels, constant velocity joints (CV joints) are utilized. CV joint failure eventually results in the car's inability to operate, however such tragic effects seldom occur right away. As a result, if a noise during movement (typical crunch) is detected, it is important to evaluate the quality of these hinges promptly and, if required, replace them with new ones as soon as possible.

TMI TATSUMI constant velocity joints are made from high-quality steel in specialist factories, and their working surfaces are hardened using high-frequency currents to provide the requisite hardness and service life. Internal friction is reduced to a minimum by the high-quality lubricant provided with the CV joints, which adds to the unit's long-term efficient functioning on the automobile.

CV joints operate in harsh circumstances beneath the hood of a moving car. Anthers created specifically for this purpose protect hinges with similar angular velocities from dirt, abrasive particles, liquids, and other contaminants. This boot is crucial because if it is broken or leaks emerge, the CV joint will rapidly fail (rubbing surfaces will be worn out) and will need to be replaced.

TMI TATSUMI constant velocity joint dusters are composed of high-quality synthetic rubber that maintains its properties even when exposed to extreme temperatures, chemically active chemicals, abrasives, and severe mechanical stress. Anther clamps are constructed of stainless steel, ensuring that the device is simple to assemble and that the anthers are securely held in place during their operation.

Because they are in direct touch with road grit and dirt, bitumen particles, water, gasoline, and oil at a range of temperatures, the drive shafts of front-wheel drive automobiles are subjected to large torsional stresses and function in extremely difficult circumstances. As a result, the materials utilized, the surface polish, and the overall quality of the drive shafts are all subject to stringent criteria.

The automobile will simply not be able to drive if at least one drive shaft breaks.

Automotive drive shafts are manufactured under the TMI TATSUMI trademark for use in a wide range of automobiles. They are made from high-quality steel that has undergone thermal surface hardening (hardening) and anti-corrosion treatment. Furthermore, the use of high-quality efficient grease, dependable synthetic rubber anthers, and stainless steel clamps ensures that these parts and the device as a whole operate for a long time.

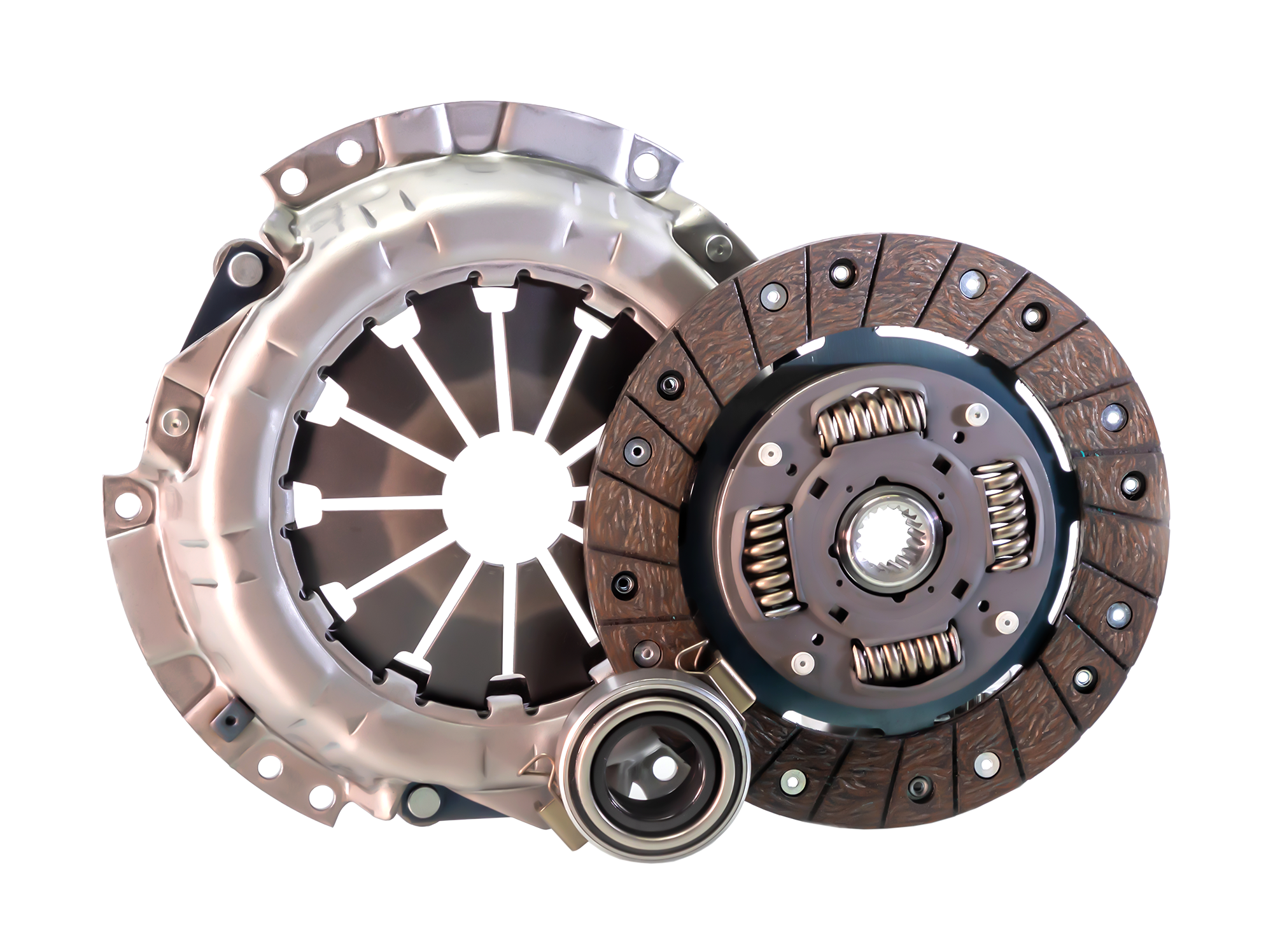

The clutch in an automobile is a vital component that is subjected to high temperatures and varying mechanical stress during operation. The clutch's job is to momentarily separate the car's engine and transmission. Partially failing clutches provide considerable issues in vehicle operation (for example, slipping clutches, partial clutch disengagement), higher fuel consumption, and fast gearbox and engine wear. The clutch's complete breakdown renders vehicle operation very difficult (failure to engage or disengage the clutch).

TMI TATSUMI clutch kits are composed of high-quality steels, and a specific friction material composition is utilized for dependable torque transfer from the engine. The petals of the diaphragm spring are shot blasted to produce a harder surface layer, greatly extending the part's overall life.

-

OE qualityOE quality

Our products are manufactured in state-of-the-art factories that supply conveyor belts to leading car manufacturers.

- - Careful selection of materials and components

- - Quality control at all stages of production

- - Product testing in our laboratories

-

Wide range ofWide range of

More than 15,000 articles of premium car components applicable to a wide variety of car modifications.

-

Product availabilityProduct availability

- - Stable availability and regular replenishment of goods in all warehouses

- - An extensive distribution network

- - 100% availability in our distribution warehouses

- - Instant and error-free order processing

-

Warranty 24 monthsWarranty 24 months

By purchasing our products, the buyer can return them within two years after the identification of a manufacturing defect. Learn more about the warranty.

-

360 customer support˚360 customer support˚

For us, the client always comes first, so we offer you:

- - Customer service 24/7

- - Hotline for technical support

- - Up-to-date catalogs and post-sales support

-

Fair pricesFair prices

Premium quality at an unbeatable price.

We are constantly improving production and optimizing logistics processes in order to offer our customers the best price.